About US

As a new brand under Anhui Forklift Group, CHL is dedicated to creating value for partners and customers by providing complete product solutions.

The CHL product portfolio covers material handling equipment from 1 to 55 tons, including internal combustion forklifts, lithium-ion battery forklifts, lead-acid battery forklifts, pallet trucks and stackers, tow tractors, heavy-duty forklifts, rough-terrain forklifts, reach stackers, empty container handlers, and more.

Our vision is to deliver reliable solutions for all lifting applications in the material handling industry.

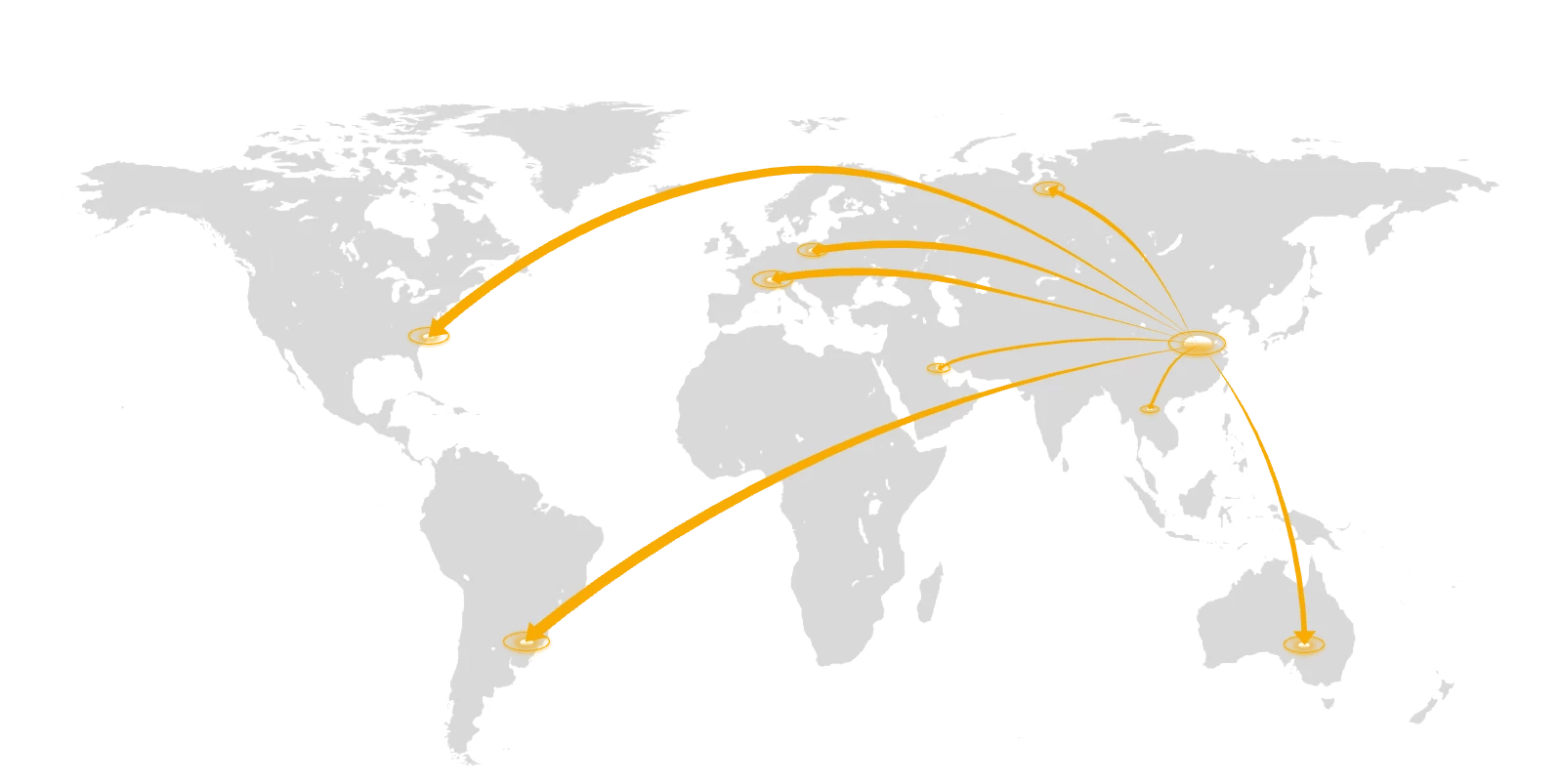

To support the global expansion of the CHL brand, Anhui Forklift Group has established eight overseas companies and one overseas research and development center.

Global Layout

-

1

in China sales & revenue

-

2

overseas research

-

8

overseas companies

-

2

in global sales

-

7

in global revenue

EMPOWER THE WORLD

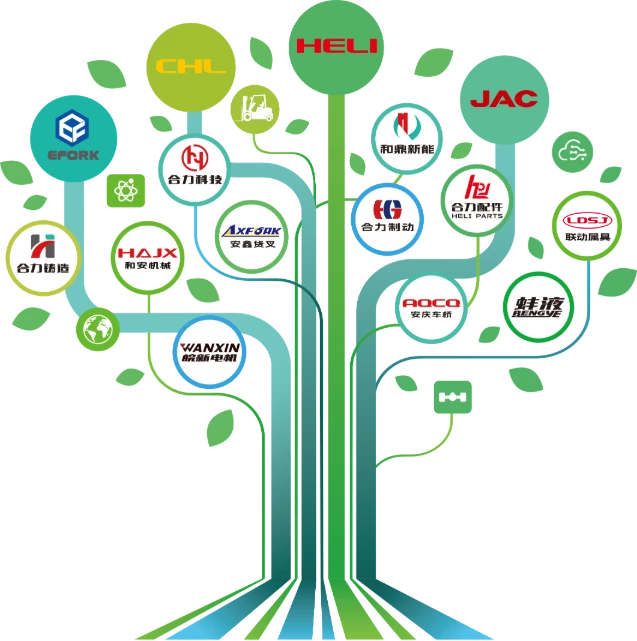

Four major machine brands

Anhui Forklift Group's four major whole goods brands, HELI, CHL, EFORK, and JAC, enable the Group to achieve comprehensive market coverage through multi-brand operations—from economy to premium segments, and from comprehensive product portfolios to specialized niche markets.

HISTORY

The CHL brand is an important part of Anhui Forklift Group, it was established in 2011.Brand history

-

1958

Origins of Anhui Forklift Group

-

1983

Transition to Specialist Forklift Manufacturer

-

1991

The Company Commenced Its Export Business.

-

2010

Successful Launch of First-Generation Dedicated Product

-

2013

CHL Entered The Southeast Asian Market.

-

2014

Expanded Into The Middle East

-

2015

Expanded Into The Americas

-

Present

CHL in The Global Market

Credible Hardy Less is more

-

Credible

With nearly 70 years of technological accumulation and verification under various working conditions, Anhui Forklift Group has consistently adhered to international standards and specifications. Through rigorous testing and validation, it ensures that the forklifts remain stable and reliable during long-term operation, with a low failure rate, thus guaranteeing the uninterrupted flow of the operation process.

-

Hardy

With high-standard design, high-strength materials, and intelligent manufacturing processes, our forklifts are safer, more efficient, and more durable. At the same time, it reduces the frequency of repairs and replacements, thereby cutting down on operating costs.

-

Less is more

It means that the forklift features a concise design and intuitive operation, which is easy to understand and use, thus reducing users' learning costs. Meanwhile, it also adopts advanced technologies and innovative solutions to meet complex requirements with user-friendly technologies.

WHY CHL

-

67-year professional experience

-

The most complete product line

-

Reliable and stable quality

-

11,000 professional employees

-

Strong after-sales service support

-

Long-term partnership

R&D system

Our development system encompasses key component mechanisms such as axle development, gearbox development, attachment development, motor development, battery development, etc. Our research area covers basic technology research, new product R&D, trial production testing, and product validation.

The product R&D management system based on the IPD concept ensures full life cycle management of products and enhances the six core capabilities of market planning, product portfolio management, development process management, platform management, collaboration management, and R&D innovation culture.

Our IPD-based product R&D management system ensures a full product lifecycle management while enhancing six core competencies: market planning, product portfolio management, development process management, platform management, collaboration management, and R&D innovation culture.